A printed circuit board (PCB) is used to support and connect electronic components using conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate. They are manufactured by a variety of methods including photo-lithography. A PCB allows signals and power to be routed between physical devices. They are used in a wide range of electronic devices, from simple circuits to complex computers. The first PCBs were developed in the early 1900s and were used to connect telephone exchanges.

The development of the integrated circuit in the 1960s led to the development of the modern PCB. PCBs can be simple, with a few components, or complex, with many layers and components. The number of layers is determined by the complexity of the circuit. Simple PCBs are used in devices such as calculators and digital watches. Complex PCBs are used in computers and other electronic devices. The manufacturing process of a PCB in FS Tech starts with the design of the circuit. The circuit is then transferred to a photoresist-coated copper sheet. The exposed copper is then etched away, leaving the desired circuit. The circuit is then transferred to the substrate, which can

1. The Printed Circuit Board: From Prototype to Production

As the world of electronics continues to evolve, so does the technology used to create and manufacture the products we use every day. Gone are the days of hand-wiring and soldering components onto a breadboard. Today, printed circuit boards (PCBs) are the standard for most electronics projects, from your average home computer to the space shuttle.

So, what is a printed circuit board? Simply put, a PCB is a board used to house electronic components and connect them together using conductive tracks or traces. These tracks are usually made from copper, but can also be made from other conductive materials like gold or silver. The tracks are etched onto the board using a chemical or photolithographic process, and the resulting board is then populated with components using soldering or other methods.

PCBs can be single or double-sided, with the components mounted on one or both sides of the board. More complex boards can have multiple layers, with the tracks on each layer interconnected using vias (holes drilled through the board).

The tracks on a PCB are typically very thin, and the spaces between them are even thinner. This high degree of accuracy is necessary to ensure that the components on the board are properly connected. The width of the tracks and spaces is typically measured in microns (millionths of a meter).

Now that we know what a printed circuit board is, let's take a closer look at how they are made.

Most PCBs are made using a process called photolithography. This process starts with a glass or quartz plate coated with a light-sensitive material called a photoresist. A mask is then placed over the photoresist, and the entire assembly is exposed to ultraviolet light. The ultraviolet light causes the photoresist to harden in the areas not covered by the mask.

The mask is then removed, and the photoresist is developed, which exposes the areas of the glass or quartz plate that will be etched. The exposed areas are then etched away, leaving behind the desired tracks.

Once the etching is complete, the photoresist is removed, and the resulting PCB

2. The Evolution of the Printed Circuit Board

The printed circuit board (PCB) has come a long way since its humble beginnings in the late 19th century. Today, PCBs are an integral part of almost every electronic device, from smartphones and laptops to industrial equipment and military hardware. In this blog, we'll take a look at the evolution of the PCB, from its early days as a crude prototype to its current status as a mass-produced commodity.

The first printed circuit board was invented in 1876 by English inventor Charles Dickens. Dickens' PCB was a crude prototype made from a sheet of copper foil and a piece of cardboard. It was not until 1903 that the first commercial PCB was manufactured, by German engineer Paul Eisler. Eisler's PCB was made from a thin sheet of copper clad laminate, and was used to connect various electronic components together.

The first mass-produced PCB was created in 1927 by American engineer Charles Doolittle. Doolittle's PCB was made from a thin sheet of Bakelite, and was used to connect electronic components in radios. The first PCBs were hand-made, and were very expensive.

It wasn't until the 1950s that PCBs began to be mass-produced. The first automated PCB production line was created in 1953 by German engineer Fritz Bener. Bener's production line was able to mass-produce PCBs at a fraction of the cost of hand-made boards.

Today, PCBs are mass-produced using a variety of different materials and processes. The most common material used for PCBs is FR-4, a type of fiberglass. FR-4 is a strong and durable material that can withstand high temperatures. Other common materials used for PCBs include polyimide and PET.

PCBs are manufactured using a variety of different processes, including etching, lamination, and plating. Etching is the process of using chemicals to remove unwanted copper from the PCB. Lamination is the process of bonding layers of material together. Plating is the process of adding a thin layer of metal to the PCB.

PCBs are used in a wide variety of electronic devices, from computers and cell phones to industrial equipment and

3. The Printed Circuit Board in Modern Electronics

The printed circuit board, or PCB, is a central component of modern electronics. It is the foundation upon which electronic components are mounted, and the pathways that connect them together. The PCB is responsible for delivering power to the components and providing the electrical connections between them.

Today, PCBs are used in a wide variety of electronic devices, from simple circuit boards to complex multi-layer boards. They are an essential part of the electronic manufacturing process, and have undergone a number of important changes in recent years.

The history of the PCB can be traced back to the early days of electronics. In the early 1900s, electronic components were often hand-soldered onto copper foil sheets. This process was time-consuming and expensive, and it was not long before manufacturers began searching for a better way to create circuit boards.

In the 1930s, the first printed circuit boards were developed. These early boards were made by photolithography, a process that used light to transfer a pattern onto a photosensitive material. This process was used to create the first printed circuit boards for military applications.

After the Second World War, printed circuit boards began to be used in a wide variety of consumer and industrial products. In the 1950s, the first commercial PCBs were produced, and the technology continued to evolve rapidly.

The early PCBs were single-sided boards, with all of the components and connections on one side of the board. These boards were used for simple electronic circuits. As the technology progressed, double-sided and multi-layer boards were developed, which allowed for more complex circuits.

The modern PCB is a complex and sophisticated device, and the manufacturing process has changed significantly in recent years. The development of new technologies has allowed PCBs to be made with finer features and smaller dimensions.

The use of computer-aided design (CAD) has made the design process much easier, and the use of automated assembly equipment has made the manufacturing process faster and more efficient.

Today, PCBs are an essential part of the electronic manufacturing process, and are used in a wide variety of electronic devices. They are an essential component of the modern world.

4. From Prototype to Production: The Printed Circuit Board Process

As you probably know by now, a printed circuit board (PCB) is the foundation of almost all electronics. They are used in everything from your computer to your cell phone to your car. In order for a PCB to work properly, it needs to be manufactured correctly. This process can be broken down into four main steps: design, prototyping, production, and assembly.

Design

The first step in creating a printed circuit board is the design phase. This is where the circuit board is designed and all of the necessary components are selected. The design phase can be broken down into two sub-steps: the schematic phase and the layout phase.

The schematic phase is where the circuit is designed and all of the necessary components are selected. This step is usually done with the help of a computer program like Eagle or OrCAD. Once the schematic is complete, it is time to move on to the layout phase.

The layout phase is where the physical layout of the circuit board is created. This step is also usually done with the help of a computer program. Once the layout is complete, it is time to move on to the prototyping phase.

Prototyping

The next step in creating a printed circuit board is the prototyping phase. This is where the circuit board is created and tested for the first time. The prototyping phase can be broken down into two sub-steps: the fabrication phase and the assembly phase.

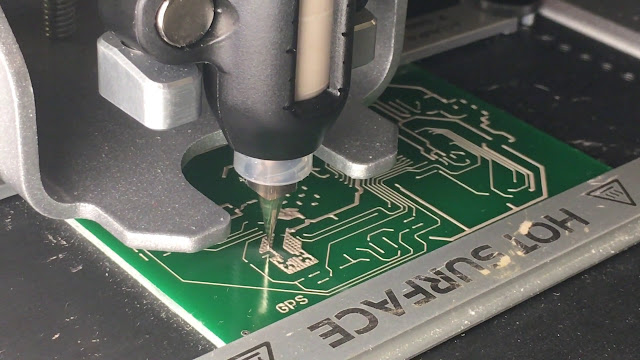

The fabrication phase is where the circuit board is actually created. This can be done either by etching the board yourself or by sending the files to a professional fabricator. Once the board is fabricated, it is time to move on to the assembly phase.

The assembly phase is where the components are soldered onto the circuit board. This step is usually done by hand, but there are also automated machines that can do it. Once the assembly is complete, it is time to move on to the production phase.

Production

The next step in creating a printed circuit board is the production phase. This is where the circuit board is mass-produced. The production phase can be broken down into two sub-steps: the fabrication

5. The Future of the Printed Circuit Board

The printed circuit board (PCB) is one of the most important components in any electronic device. It is the backbone of the device, providing support and connectivity for all the other components. The PCB is also the most visible part of the device, and so the quality of the PCB can have a big impact on the overall quality of the device.

There are many different types of PCBs, and the technology is constantly evolving. This means that the future of the PCB is always changing, and new developments can have a big impact on the way that PCBs are used.

One of the most important developments in the last few years has been the rise of flexible PCBs. These are PCBs that are made from flexible materials, and so can be bent or shaped to fit into a wide variety of devices. This has opened up a whole new world of possibilities for PCB design, and means that PCBs can be used in a much wider range of applications.

Another big development in the world of PCBs is the rise of 3D printing. This is a technology that allows PCBs to be printed in three dimensions, and so opens up a whole new range of possibilities for PCB design. 3D printing is still in its early stages, but it is already having a big impact on the world of PCBs, and is likely to have an even bigger impact in the future.

The future of the PCB is always changing, and new developments can have a big impact on the way that PCBs are used. Flexible PCBs and 3D printing are just two of the many developments that are changing the way that PCBs are made and used.